Capacity planning strategies are invented to make sure that your business has the right amount of resources at the right time to meet the demand. It’s all about that sweet balance – too much capacity means wasted resources and excess costs, while too little results in missed opportunities and dissatisfied customers.

In sum, capacity planning strategies empower you to navigate the unpredictable waters of customer needs. And in this post, we’ll explore everything about the 3 different types of such strategies: lag, lead, and match.

Let’s dive right in!

3 Primary Capacity Planning Strategies

Lag capacity planning

Lag capacity planning is a strategy where businesses hold off on increasing their production capacity until there’s a definite uptick in demand. In simpler terms, it’s like waiting to buy more chairs for your restaurant until you actually see more customers coming through the door.

Pros:

- Cost efficiency. The lag capacity planning strategy helps you avoid the heavy costs associated with premature investments in infrastructure and resources. In other words, you only scale up when there’s clear customer demand, which results in much better budget management.

- Reduced risk. If the market shifts unexpectedly or demand doesn’t materialize as anticipated, you’re not stuck with excess capacity. This approach minimizes the risk of wasted resources and helps maintain profitability.

Cons:

- Potential for lost sales. If demand spikes faster than expected, you might find yourself scrambling to keep up, ultimately disappointing customers who are eager to spend.

- Increased lead times. Since you’re scaling up production or services after demand spikes, customers might experience longer wait times. This could lead to dissatisfaction and could tarnish the company’s reputation over time.

Best for:

Lag capacity planning is best suited for businesses that enjoy a steady customer base with minimal demand fluctuations, such as utility companies and traditional manufacturing firms.

Example:

A popular coffee shop suddenly sees a surge in traffic during the holiday season (thanks in part to a viral social media post featuring their seasonal drink).

The management, caught off guard by the influx of customers, quickly realizes that their current staffing levels and inventory won’t meet the increased demand. Instead of panicking, they implement lag capacity planning:

- They bring in additional baristas on a temporary basis, ensuring their team can handle the rush without sacrificing quality.

- They also ramp up their supply orders for coffee beans, milk, and pastries to avoid running out of popular items.

- To manage the flow of customers, they enhance their online ordering system, allowing for pickup orders that can ease congestion in-store.

Despite the unforeseen demand, this agile response not only satisfied customers but also boosted sales and strengthened the coffee shop’s reputation as a go-to spot during the holiday magic.

Lead capacity planning

Lead capacity planning is all about anticipating future demand and gearing up your resources accordingly. It involves adding extra capacity to your operations beforehand so that when the demand spikes, you’re ready to dive in and make it happen.

Pros:

- Adaptability. Lead capacity planning enables you to be more agile in responding to changes in customer needs or market conditions. It encourages constant evaluation and the flexibility to adjust resources as necessary.

- Enhanced resource utilization. By understanding lead times for different processes, you can allocate resources more efficiently and make sure that your teams are not under or over-utilized. This optimal allocation keeps everything running smoothly and can save a lot of money in the long run.

- Better decision-making. With accurate lead capacity insights, you can foresee potential bottlenecks and plan accordingly. This foresight improves project timelines and reduces rush jobs that often come with higher costs (both direct and indirect).

Cons:

- Forecasting challenges. Relying on forecasts can be tricky. If assumptions are off, it can lead to underestimating demand, which puts further strain on your operations when the market surprises you.

- Initial set-up costs. Implementing a lead capacity planning strategy requires investment in tools and training. For smaller businesses, these upfront costs can be a barrier, even if the long-term benefits are significant.

Best for:

Lead capacity planning strategies are best suited for businesses that experience fluctuations in demand, particularly those in service-oriented industries like hospitality, healthcare, and retail.

Example:

A bustling seaside hotel is gearing up for the summer season. The management notices an uptick in online bookings and inquiries, signaling that this year’s demand is likely to surpass previous summers.

To tackle this surge, they decide to implement lead capacity planning:

- The team analyzes past data, focusing on trends from previous summers to predict occupancy rates, popular booking days, and room types in demand.

- Armed with this knowledge, the management increases their workforce by hiring additional front desk staff and housekeeping members, ensuring smooth check-in experiences and quick turnovers for cleaning rooms.

- Next, they ramp up marketing efforts – promoting family packages and special offers through social media and email campaigns – to attract those high-demand guests.

- They also collaborate with local attractions, offering guests exclusive discounts and creating a win-win situation that enhances the overall guest experience.

By staying ahead of the curve and preparing its operations for the influx, the hotel not only maximizes profits but also builds a reputation for exceptional customer service that keeps guests coming back year after year.

Match capacity planning

Match capacity planning is all about aligning your resources with both actual and anticipated demand in mind. The strategy promotes a more frequent analysis of true demand, projected trends, and market shifts than the lag and lead strategies require.

All in all, it teaches you to manage your capacity proactively and dynamically so you can keep pace with constant changes.

Pros:

- Efficiency maximization. The match capacity planning strategy allows you to align production or service capacity closely with demand. This means less wasted resources, as you’re not overproducing goods that might not sell.

- By focusing on matching capacity to current demand trends, you can easily adapt to changes in the market. If there’s a surge in demand for a popular item or service, the strategy enables a quicker response time.

Cons:

- Limited long-term perspective. Because this strategy centers on immediate demands, businesses might overlook longer-term planning and investment strategies that could be beneficial for sustained growth.

- Demand forecasting challenges. Accurately predicting demand on an ongoing basis can be tricky. If forecasts are off, a business might find itself either overwhelmed with too much inventory or unable to fulfill orders due to insufficient stock.

Best for:

Match capacity planning strategy is particularly well-suited for businesses that operate in industries with constantly fluctuating demand, such as manufacturing, retail, and logistics.

Example:

A local bakery prides itself on its artisanal bread and pastries.

Every Friday, the management team gathers to review sales data from the past few weeks. They’ve noticed a recurring spike in demand for sourdough loaves and croissants every weekend, particularly leading into the holiday season. With this knowledge, they implement match capacity planning:

- During the week, they ramp up the production of sourdough starters and bring in extra ingredients like flour and butter, anticipating the uptick.

- On the weekends, they even schedule additional staff for the morning rush, ensuring that there’s enough capacity to meet customer demand without turning anyone away.

This way, the bakery keeps shelves stocked and boosts customer satisfaction as locals can always rely on finding their favorite treats.

Capacity Planning Process: 5 Core Steps

Step 1: Assess current capacity

First up, take a good look at where we’re at. Evaluate the existing resources – think workforce, technology, and infrastructure. This way, you will identify any gaps or inefficiencies that might be lurking under the surface.

Step 2: Forecast future demand

Peek into the crystal ball to predict what’s coming down the pipeline. This phase is all about collecting data – from market trends to customer behavior – and using it to anticipate future needs.

It’s a bit like detective work, and while we can never be 100% right, having a solid forecast helps us prepare for various scenarios.

Step 3: Pick the right strategy

Consider your business model, market volatility, and customer expectations. If you’re in a fast-paced industry, leading might pay off. However, if you’re nurturing long-term relationships in a more stable environment, lagging could work just fine.

Don’t forget to factor in your available resources too – sometimes your choice will be dictated by what’s feasible.

Step 4: Implement changes

Whether you’re looking to ramp up production, manage resources more effectively, or simply make room for new projects, here are a few common tactics that can help you get there:

- Streamlining processes. Sometimes, the best way to change capacity is to look at your current processes and see where you can cut the fat. This might mean automating repetitive tasks or reorganizing workflows. Efficiency is king!

- Flexible resources. Leveraging temporary labor or outsourcing can give you the flexibility to scale up when demand spikes without the long-term commitment. It’s like having an emergency boost at your fingertips.

- Investing in technology. Upgrading your equipment or software can dramatically enhance your output. Think about it – better tools lead to faster turnaround times. It’s not just about keeping up but about staying ahead.

Step 5: Monitor and adjust

This is an ongoing task where you keep an eye on performance metrics and feedback to ensure you’re hitting your targets.

One effective way is through setting up key performance indicators (KPIs) that track essential metrics like response times, lead time, and customer satisfaction. This data gives you real-time insights into how well your adjustments are holding up.

Another common tactic is employing performance monitoring tools that help to stay in control of ongoing workloads and show when your team’s capacity nears its limits.

Take actiTIME as an example – it’s a fantastic tool for keeping your team’s workload in check and ensuring that no one gets overwhelmed:

- By offering a dynamic time tracking feature, it lets you easily log hours spent on tasks, providing you visibility into where those precious minutes are going. This real-time insight means you can quickly spot potential bottlenecks before they spiral out of control.

- It also features the Kanban board that turns work management into a visual experience. You can move tasks across different stages, see what’s in the queue, and adjust workloads on the fly, making collaboration a breeze.

- actiTIME’s performance reports give you in-depth analytics about team productivity and project progress. With these reports, you can spot trends, measure efficiencies, and ultimately ensure your team’s capacity remains balanced.

Together, these features make actiTIME an invaluable ally in maintaining control over workloads while keeping your team happy and productive.

Sign up for a free 30-day trial here.

Use a Reliable Resource Scheduling Tool to Step Up Your Capacity Planning Game

A good resource scheduling tool is a must-have if you seek to optimize your resources and maximize productivity. By visualizing workloads and resource availability, it enables you to allocate assets more efficiently, prevent bottlenecks, and rest assured that no one is overextended.

A great example of such a tool is actiPLANS, a flexible resource scheduling solution that streamlines a bunch of essential processes.

Here are some of its standout features that truly come in handy for capacity planning:

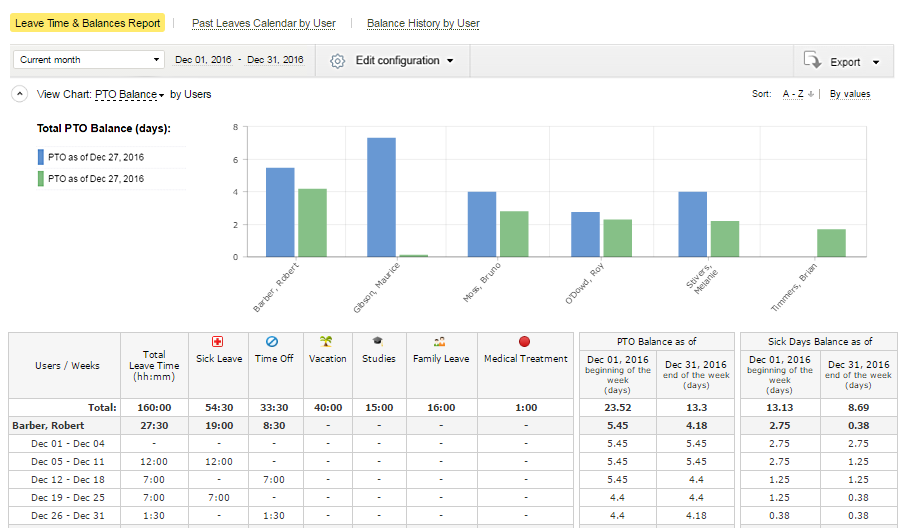

- actiPLANS automates leave requests and approvals, giving you a clear picture of available resources without the constant back-and-forth emails.

- A visual resource schedule allows you to see your team’s availability at a glance. You can easily identify gaps, allocate resources efficiently, and ensure that no project is left understaffed.

- actiPLANS provides detailed reports on attendance and absence patterns, helping you make informed decisions about staffing needs. This insight helps in identifying trends that could impact your capacity planning.

- actiTIME integration lets you marry time tracking with capacity planning for better performance results. It allows for real-time data capturing and analysis of how resources are utilized versus how they are planned. You can assess performance metrics and make adjustments on the fly.

By streamlining various aspects of workforce management, actiPLANS ensures that you not only stay ahead of the curve but also enhance productivity across the board.

Sign up for a free 30-day trial to check it out in action yourself.